Casting Techonology

HOVADUR® special alloys showing excellent thermal conductivity are essential materials for construction in casting technology

Browse Casting Technology applications

About Casting Technology

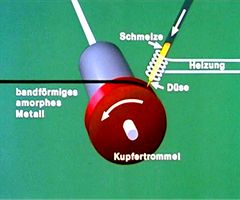

Casting Technology

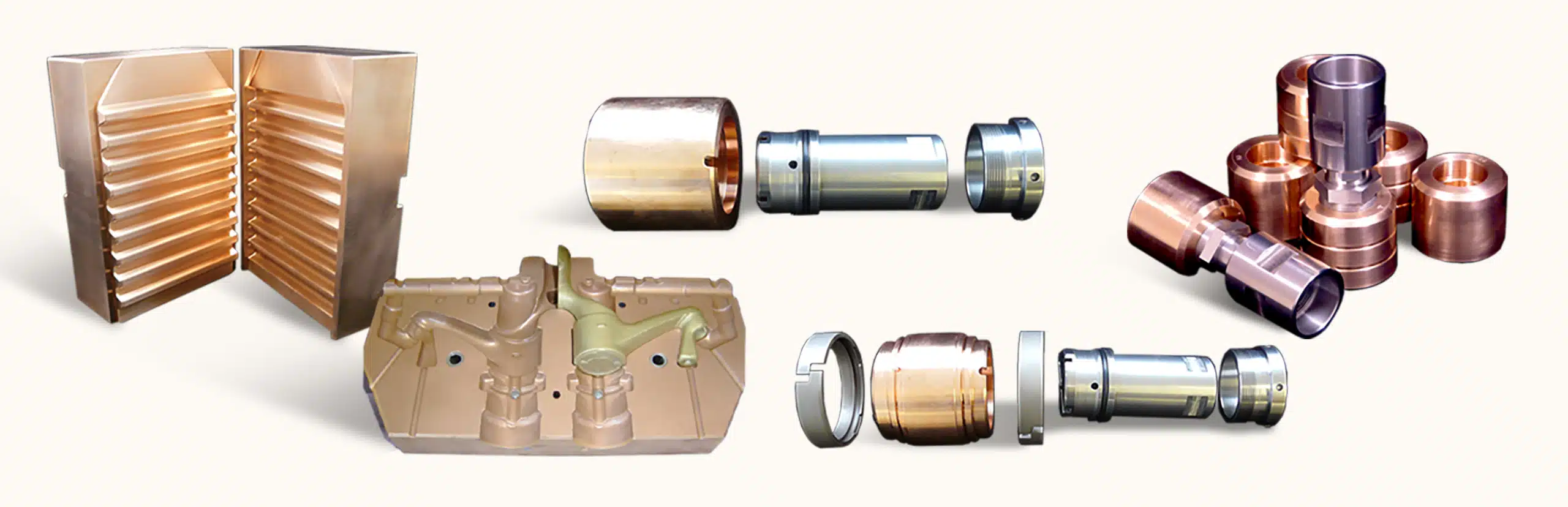

Your advantages:

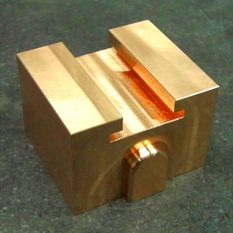

- Low piston wear

- Increased lifespan of the shot chamber

- Simple handling of the piston system

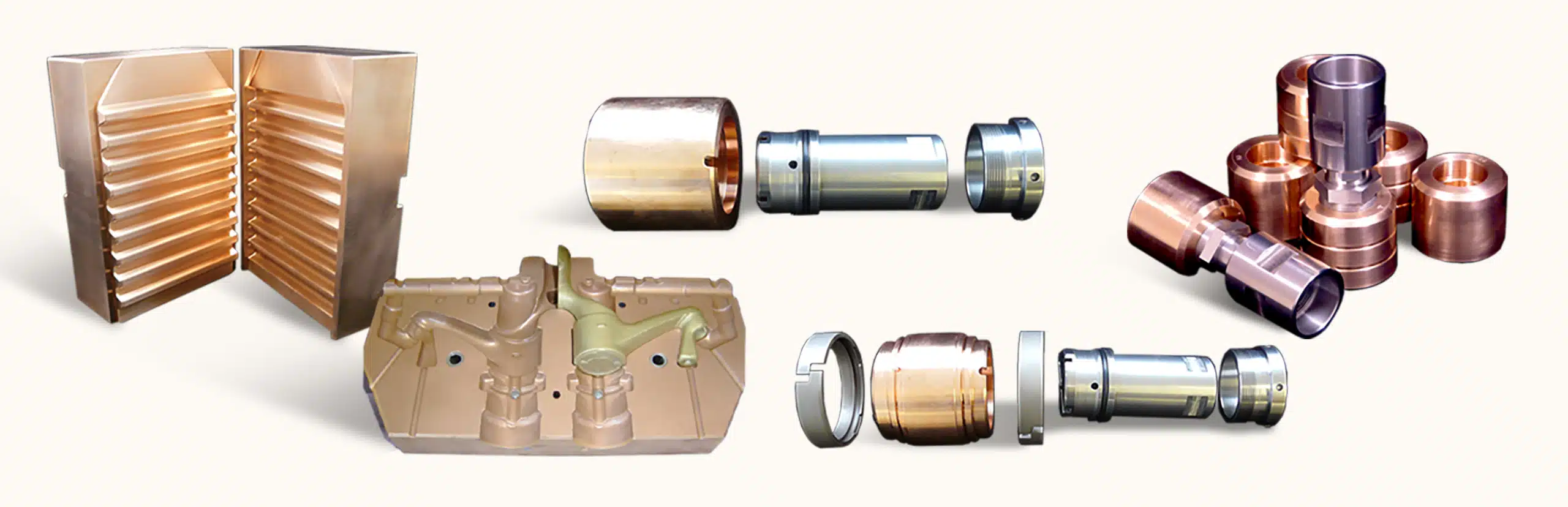

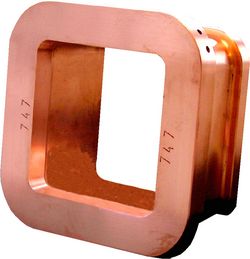

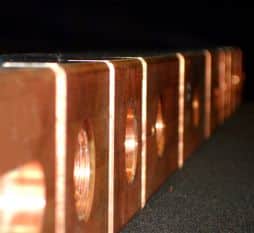

Our range of products:

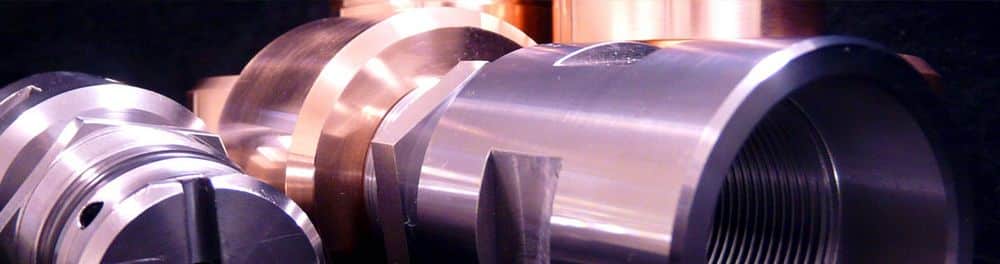

- Pistons > Piston Adapter Systems

- Shot chambers

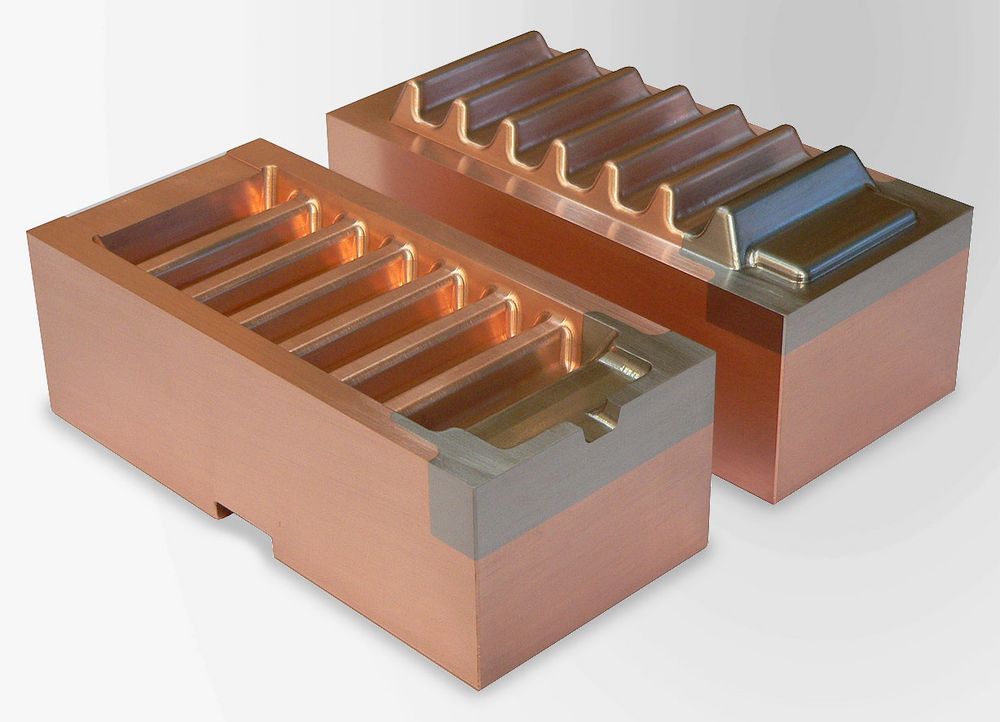

- Die venting systems

- Moulds for continuous casting