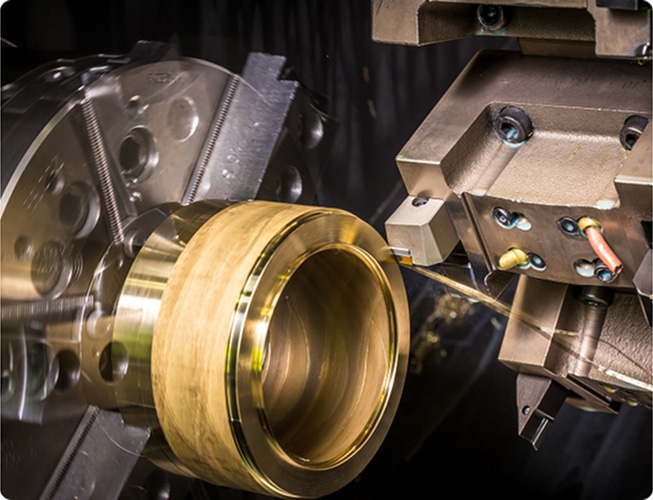

Vacuum technology for maximum performance

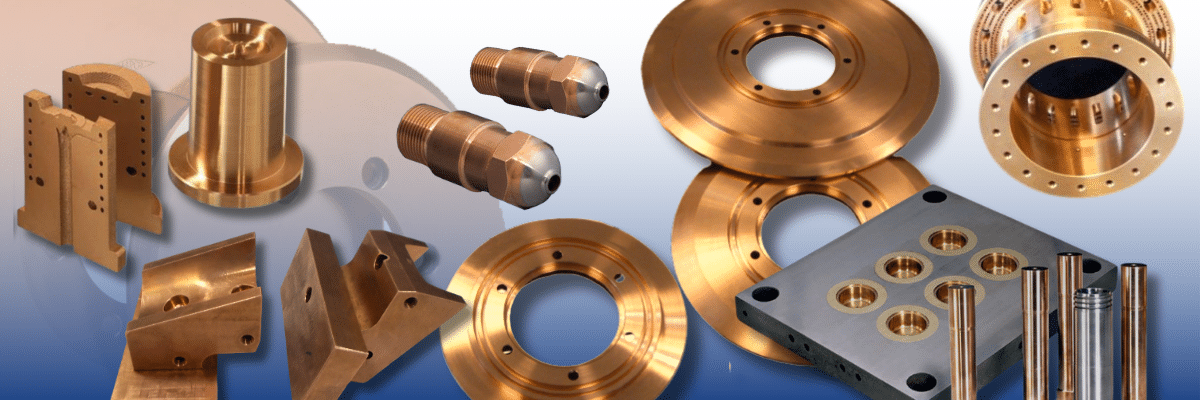

Established in 1959, we have become a leading manufacturer of high-performance copper-based alloys

About SCHMELZMETALL

We are represented all over the world by an internationally acting sales teams and branches. Our HOVADUR® alloys stand for highest quality and a fair price-performance ratio.

We are experienced in high-vacuum copper alloy production, we deliver consistent, exceptional quality. Our expertise extends to the further processing of both semi-finished and finished parts, ensuring optimal performance in every stage. We understand how to apply our alloys effectively within your processes and applications while maximizing reliability, precision, and results.

Company history

1959

Foundation of SCHMELZMETALL AG, Headquarters in Gurtnellen, Switzerland.

Production of copper alloys in a 50 kg vacuum induction furnace.

Production of ultra-pure chromium in an electrolysis plant.

1962

Increase of the melting capacity by a 300 kg vacuum induction furnace.

1964-1970

Expansion of mechanical processing for ingots and semi-finished products.

1974

Commissioning of a plate shear for cutting the copper cathodes

1981

Commissioning of an automated band saw.

Investment in overhead travelling crane system for the copper warehouse.

1982

Capacity expansion of the electrolysis plant for ultra-pure chromium

1983

Construction and facility installation of the production hall 5.

1984

Commissioning of a 1000 kg vacuum induction melting and casting plant.

Investment in a heat treatment plant.

1986

Development of the special alloy for the combustion chamber of the Ariane 5 rocket.

Expansion of the electrolysis plant for ultra-pure chromium in hall 1.

1989

Commissioning of a 500 kg “two-chamber vacuum induction melting and casting plant” to increase the casting capacity

1991

Certification according to DIN ISO 9000 / SN ISO 9000 as one of the first Swiss companies.

1995

Conversion of the 1000 kg vacuum furnace to 1500 kg casting weight.

1997

Foundation of the Service Center SCHMELZMETALL Deutschland GmbH, based in Steinfeld-Hausen (Bavaria).

2000

Market launch of our HOVADUR® product line.

2001

Acquisition of the production plant SCHMELZMETALL Hungaria Kft, based in Budapest (Hungary) with vacuum melting and casting machines for casting weights of 10 kg, 550 kg and 1500 kg.

2004

Acquisition of a second office building in Steinfeld-Hausen.

2005

Market launch of our HOVADUR® B aluminum bronzes.

2006

Market launch of our own product lines HOVATOP®, HOVABOND® und HOVAVENT®

2007

Extension by a central warehouse (hall 6) with 1.250 m² storage area in Steinfeld-Hausen.

2008

Capacity expansion of the Service Centre in Steinfeld-Hausen by four CNC-machining centres;

Extension of the second office building in Steinfeld-Hausen with a second floor

Research and development: InnoSurface 16IN0587

Development of the innovative tools on the basis of surface-functionalized generatively manufactured mould inserts

Validity period: 01.01.2008 – 30.06.2011

2009

Research and Development: KF2315301CK9

Innovative components made of copper-based materials with local wear protection by laser cladding using the example of hot runner nozzle and pre-chamber bushing

Validity period: 01.07.2009 – 30.06.2011

2010

Conversion of the biggest vacuum furnace in Hungary to a capacity of 1.900 kg.

Permanent expansion of the CNC machinery park in Steinfeld-Hausen from 2010 to 2015.

2011

Research and Development: KF2315302CK1

Innovative machine components made of copper alloys with local wear protection by laser cladding for plastic injection moulding and light metal die casting

Validity period: 01.11.2011 – 30.06.2014

2012

Research and Development: EU – Cornet – Project

Advanced Coil Design for Electromagnetic Pulse Technology (ACODEPT)

Validity period: 01.01.2012 – 31.12.2013

Research and Development: KU2315303TL2

Innovative welding tong systems for resistance welding based on composite and copper materials

Validity period: 01.03.2012 – 31.03.2015

Research and Development: KF2315304FH2

Optimization of tribologically highly strained sliding surfaces in high-pressure pumps and motors in mobile hydraulics by using novel, lead-free copper alloys.

Validity period: 15.10.2012 – 31.12.201

2013

Mr. Werner Bochmann handed over the management of SCHMELZMETALL Deutschland GmbH to Mr. Edgar Seufert (sales management) and Mr. Markus Heinrich (purchasing management).

2014

Research and Development: AZ-1117-14

Generative production processes in tool and mould construction – ForNextGen – Additive multi-material construction of tools and moulds. Project within the framework of the Bavarian Research Foundation

Validity period: 01.09.2014 – 31.08.2017

2016

Investment in the worldwide unique special machine for round bar production; Capacity expansion of the Service center in Steinfeld-Hausen by a new production hall (Hall 7);

Relocation of the complete machine park to the new hall 7

2018

Construction of a special area for 3-D printing in our production hall at our German site

2019

At our German facility, we provide heat treatment for printed parts as a service to our customers.

Technical approval of a 3-D printer for copper alloys at Messrs. SLM Solutions in Lübeck and installation at our German site

2024

Acquisition of Schmelzmetall by AMPCO METAL

In October 2024, the Schmelzmetall Group was acquired by AMPCO METAL, a global leader in high-quality copper-based alloys. This strategic acquisition has strengthened our product portfolio, expanded our production capabilities, and reinforced our global presence.

Our experience – your advantage

Locations

Schmelzmetall AG

SCHMELZMETALL AG was founded in 1959 and is the parent company of SCHMELZMETALL group. The head office is located in Gurtnellen in the idyllic Swiss canton Uri.

SCHMELZMETALL Deutschland GmbH

SCHMELZMETALL Deutschland GmbH was founded in 1997 as a service center located in Steinfeld-Hausen (Bavaria).

SCHMELZMETALL Hungária Kft.

SCHMELZMETALL Hungária KFT. was founded in 2001 and is located in Budapest, Hungary.

Latest news and events

Learn more about us

1 results