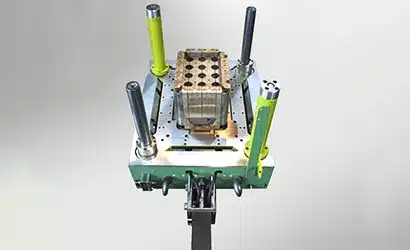

Plastic Injection Moulds

Today’s injection molds must meet increasingly complex and sometimes conflicting requirements: delivering the highest part quality while minimizing cycle times. HOVADUR® alloys meet these challenges through a combination of properties that make them ideally suited for high-performance molding applications

Browse Plastic Injection applications

About Plastic Injection Moulds

Plastic Injection Moulds

Our alloys are characterized by:

- High thermal conductivity

- High resistance to wear

- High elongation

- Good machining

- Good surface coatability

- Good structuring properties of surfaces

- Good chemical stability

Your advantages:

- Shortest cycle time

- Highest quality of the moulded part

- High added value

- Low machining costs

- Uniform cooling

Our range of products:

- Semi-finished products for your mould construction

- Mould inserts pre-machined close to the contour

- Steel / copper composite according to your guidelines

- Injection nozzles and ante-chamber bushings

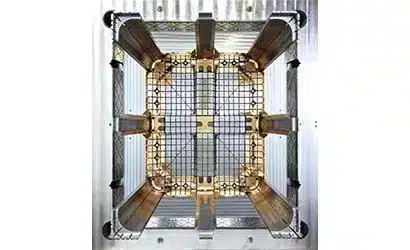

- Generatively produced mould inserts

Longitudinal section of a generatively produced mould insert made of HOVADUR® K220

Types of Plastic Injection Applications

Select from the range of applications below to find out more.